Vacuum Metallurgy

-

Iqondo lobushushu eliPhezulu eliPheleleyo eliSebenzayo eliQinisayo leSintering...

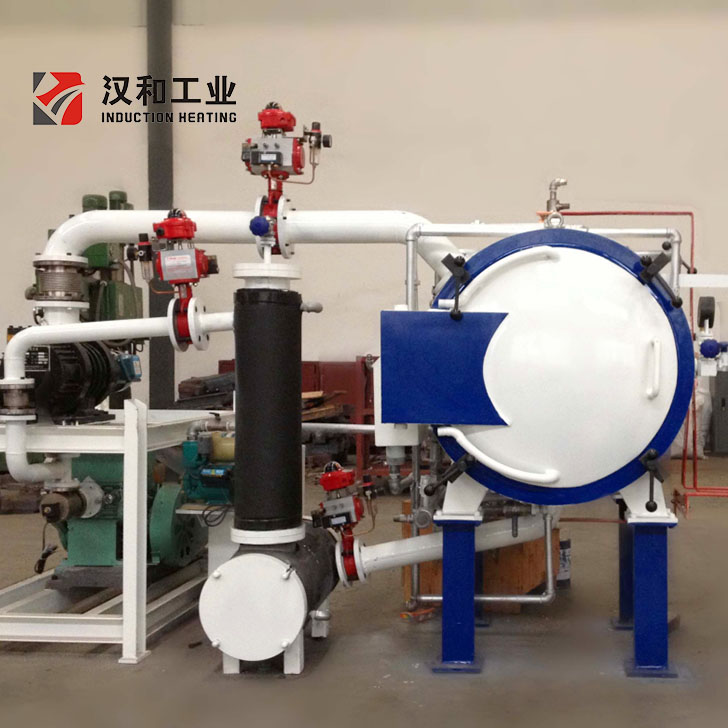

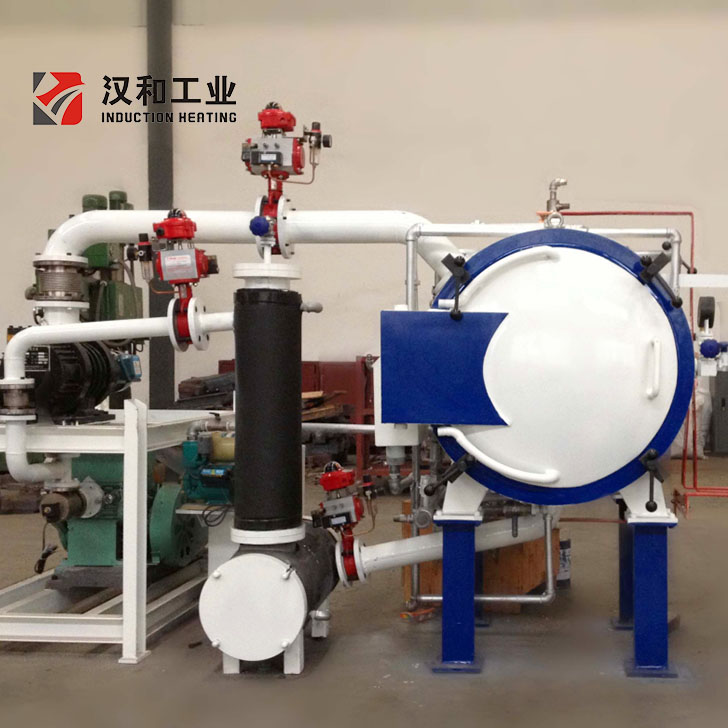

I-vacuum sintering furnace sisithando somlilo esisebenzisa ukufudumeza kwe-induction ukutshisa izinto ezishushu ngokukhusela.I-vacuum induction sintering furnace yiseti epheleleyo yezixhobo zokufakwa kwe-carbide kunye nomgubo wesinyithi ohlukeneyo ngokusebenzisa umgaqo wokufudumeza okuphakathi kwamaza omoya phantsi kwe-vacuum okanye iimeko zokukhusela umoya.Yenzelwe ukuveliswa kwemveliso ye-alloy enzima, i-metal dysprosium kunye nezixhobo ze-ceramic.

-

Ubushushu obuphezulu beGraphite Furnace

I-graphite furnace sisixhobo soshishino esinokwenza igraphite kwiindidi zamatye kunye neekhemikhali.Ingasetyenziselwa ukwenza izinto zegraphite ezinomgangatho ophezulu, ukusebenza okuphezulu kunye nokuhamba kombane okunamandla.Kukho iintlobo ezininzi zesithando somlilo segraphite, uhlobo lwenqwelomoya oluqhelekileyo, oluthe nkqo, uhlobo lokumiswa, uhlobo lolwelo njalo njalo.

-

Iziko lokuKhula leCrystal enye

I-crystal furnace enye ikwabizwa ngokuba yi-mono crystal furnace, sisixhobo esinyibilikisa izinto ze-polycrystalline ezifana ne-polysilicon ene-graphite heaterin i-inert gas (i-nitrogen kunye ne-helium gas) kwaye ikhulise i-crystals enye ngaphandle kokuchithwa ngokusebenzisa indlela yokutsala ngokuthe ngqo.

-

I-Polysilicon Ditrctional Soldificatiion Furnace

Isithando somlilo esisisikhokelo sisixhobo sanamhlanje esisebenzela ukunyibilika kwesinyithi okanye ialloy kunye nokufudumeza okuphakathi kwe-frequency induction phantsi kwe-vacuum, senza i-thermal gradient eneziko elikhethekileyo eliyiliweyo kunye nenkqubo yokupholisa, kunye nokulungiselela ukuqiniswa kunye nekristale enye ngokutsala phantsi.Inokulawula ngokungqongqo ubushushu kunye nomxholo we-alloy wezinto.Ukufumana iqondo lobushushu eliphezulu kakhulu kunye nojongano olugudileyo lokuqina, yamkelwa ngokuchongwa okukhethekileyo kwimfuno yayo yomgangatho wobushushu.I-furnace yethu yokuqinisa i-directional yenzelwe ngendlela ethe nkqo kunye nomsebenzi omncinci wendawo kwi-workshop.

-

Isiko lokuNyibilikisa lokunyibilikisa leVacuum elungiselelweyo

Ukunyibilika kweVacuum Induction Melting (VIM) kukunyibilika kwesinyithi nge-electromagnetic induction phantsi kwevacuum.Isithando somlilo esine-refractory lined crucible ejikelezwe yi-coil induction ifumaneka ngaphakathi kwegumbi lokucoca.I-oven induction iqhagamshelwe kumthombo wamandla kwi-frequency ehambelana ngokuchanekileyo nobukhulu besithando somlilo kunye nezinto ezinyibilikayo.