Iziko leMveliso

-

Iziko lokuNyibilikisa eliPhezulu leFrequency Frequency Melting for Pr...

Isithando somlilo esinyibilikisayo esiphakamileyo sisetyenziselwa ukunyibilika kunye nokuphosa isinyithi esixabisekileyo esinjengegolide, isilivere njl.njl esetyenziswa kubucwebe kunye ne-artware kumashishini amakhulu okunyibilikisa kunye nobungakanani obuncinci obuxabisekileyo bokulungisa isinyithi.

-

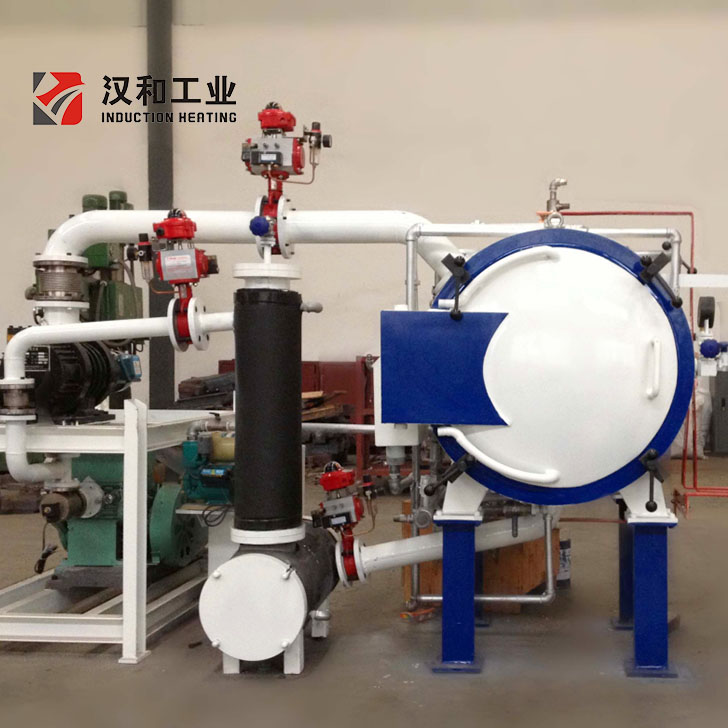

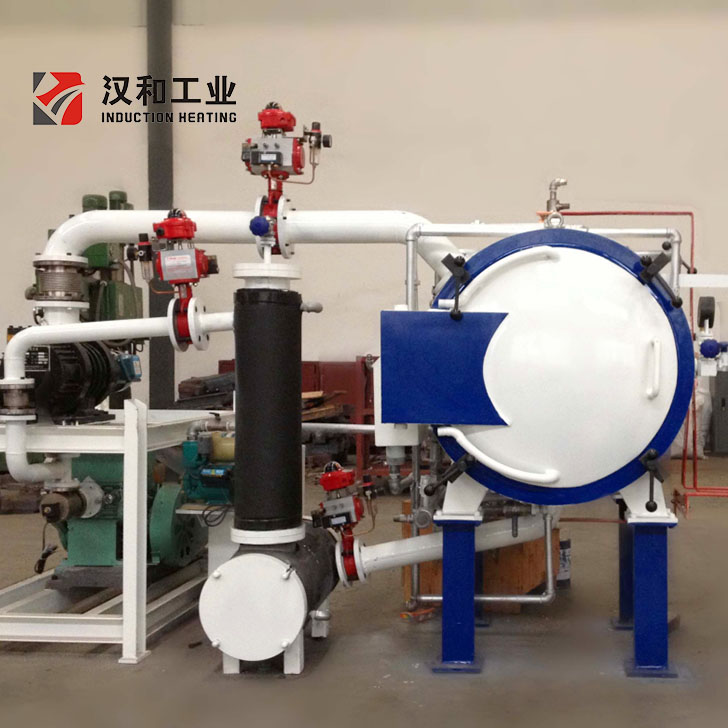

Isixhobo se-Atomization yegesi ye-Metal eSpherical

Isixhobo se-vacuum ye-atomization yegesi yeyokwenziwa komgubo wesinyithi kwisiseko se-VIGA yaseYurophu.Isetyenziselwa iziko le-R&D kunye neeyunivesithi ukufunda umgubo wesinyithi ongqukuva kunye nesiqingatha semi-spherical kunye nemveliso yobuninzi yeefektri.

-

I-Atomizer yaManzi-Gesi eDityanisiweyo ye-Soft Magnetic A...

Isixhobo se-atomization somoya wamanzi sinobukrelekrele obuphezulu, sisebenza kakuhle, kwaye sisebenza ngokuphezulu isixhobo se-atomization esisetyenziswa ikakhulu kwizixhobo zobugcisa obuphezulu ekuphuhliseni nasekuveliseni izinto ezintsha kwiinkalo ezifana ne-aerospace, i-aviation, kunye nobukrelekrele.Umgaqo-nkqubo wokusebenza wesixhobo ngokuyinhloko ngokufudumeza ukufudumala kwe-induction, okunyibilikayo kunye nokufaka izinto eziqinileyo zetsimbi ngokufudumeza kwe-induction.Ulwelo lwesinyithi olunyibilikisiweyo lugalelwa embizeni ephakathi, kwaye luhamba ngombhobho wesikhokelo kwisixhobo se-atomization.Xa ihamba ngepleyiti yokutshiza ukuya kumbhobho we-atomization, amanzi oxinzelelo oluphezulu atshizwa ngaphandle koxinzelelo oluphezulu lomlomo wepleyiti yokutshiza ukuze enze indawo ye-atomization. kwaye iphucula kakhulu umgangatho kunye nokusebenza kwemveliso, ngakumbi ukuveliswa kwezixhobo ezineemfuno eziphezulu zokungeniswa kwemagnethi.

-

I-Electrode eJikelezisayo yokuNgenisa iGasi yokuFudumeza...

I-EIGA i-electrode induction inyibilika izixhobo zegesi ye-atomization engasebenziyo iyanyibilika kwaye icokise ibar ye-electrode esele yenziwe kwindawo yerhasi engasebenziyo ngaphandle kwe-ceramic crucible.Isinyithi esityhidiweyo sidlula kwi-nozzle ngokuqhubekayo kwaye ngokuthe nkqo.Isinyithi esinyibilikisiweyo sityunyuzwa kwaye sifakwe kwinani elikhulu lamathontsi amancinci ngokuhamba komoya ohamba ngesantya esiphezulu, kwaye amathontsi aqina xa ebhabha ukuze enze umgubo ongqukuva.Umxube wegesi ye-powder uthunyelwa kwi-separator ye-cyclone epholileyo yamanzi ukuze ihlukaniswe nge-tube yokuhambisa.I-fine metal powder iqokelelwa kwi-vacuum etywiniweyo yokuqokelela umgubo.

-

Umatshini wokuBonga uMbhobho wokuFundisa ngoomatshini

WGYC serial umbhobho ukugoba umatshini kukulungisa zombini iziphelo umbhobho yentsimbi.Seta iradiyasi yokugoba kwelinye icala, kwaye utyhale esinye isiphelo phambili ukuze ugobe ngesantya esingaguqukiyo.Umbhobho wensimbi ufudunyezwa kwindawo nge-coil yokufakelwa kwe-electromagnetic.Xa ugoba, umbhobho wentsimbi uqhutywa zizikrufu ezichanekileyo eziphezulu zimbini kwaye zipholile ngokuqhubekayo kunye nendawo yokupholisa efanelekileyo ukuya kwi-engile yokugoba efunekayo.Ingasetyenziselwa ukugoba okutshisayo kweentlobo ezahlukeneyo zombhobho wensimbi ojikelezayo okanye wesikwere, umbhobho ongenasici kunye nentsimbi edibeneyo, kwaye iyasebenza kwi-petroleum, imboni yeekhemikhali, i-metallurgy, isakhiwo sensimbi kunye nebhoyili njl.

-

I-Stainless Steel Pipe Bender ene-Spool Ukugoba

Umbhobho we-induction bender kunye ne-spool bending ixhotyiswe ngesixhobo sokuguqula i-3D bends.Isixhobo esijikelezayo senza ukuba ityhubhu / umbhobho uguqulwe ngokuzenzekelayo nge-90 °, oku kuthetha ukuba ukugoba kwe-3D (i-spools) kunokuveliswa ngakumbi ngokwezoqoqosho nangokuchanekileyo.

-

I-Polysilicon Ditrctional Soldificatiion Furnace

Isithando somlilo esisisikhokelo sisixhobo sanamhlanje esisebenzela ukunyibilika kwesinyithi okanye ialloy kunye nokufudumeza okuphakathi kwe-frequency induction phantsi kwe-vacuum, senza i-thermal gradient eneziko elikhethekileyo eliyiliweyo kunye nenkqubo yokupholisa, kunye nokulungiselela ukuqiniswa kunye nekristale enye ngokutsala phantsi.Inokulawula ngokungqongqo ubushushu kunye nomxholo we-alloy wezinto.Ukufumana iqondo lobushushu eliphezulu kakhulu kunye nojongano olugudileyo lokuqina, yamkelwa ngokuchongwa okukhethekileyo kwimfuno yayo yomgangatho wobushushu.I-furnace yethu yokuqinisa i-directional yenzelwe ngendlela ethe nkqo kunye nomsebenzi omncinci wendawo kwi-workshop.

-

I-100kg ye-Atomizing yaManzi yoMshini we-Metal Powder

Inkqubo yeAtomization yamanzi ibhekiselele kwinkqubo yokutshiza kunye nokungqubana kwamanzi kuxinzelelo oluphezulu malunga ne-50-150 MPa ngokuchasene nesinyithi esinyibilikisiweyo kubushushu obuphezulu ukuvelisa umgubo wesinyithi ocolekileyo (umgubo owenziwe nge-atomized) kwinqanaba le-micron.Emva kokuba i-alloy etyhidiweyo (isinyithi) inyibilikisiwe kwaye icocwe kwiziko lokungeniswa, ulwelo lwesinyithi olutyhidiweyo lugalelwa kwi-crucible yokugcina ubushushu kwaye lungene kwityhubhu yokuguqula.Uxinzelelo oluphezulu lokuhamba kwamanzi kwitreyi yokutshiza luyakutyumza kwaye lufake iatomize ulwelo lwesinyithi lube ngamathontsi amancinci kakhulu.Iidrophu zetsimbi ziya kuqinisa kwaye ziwise kwinqaba ye-atomization, kwaye emva koko iwele kwitanki yokuqokelela umgubo.I-powder slurry eqokelelweyo ihluzwa ngoxinzelelo lwe-pressure dehydration, ukoma kunye nokuhlolwa.

-

Iqondo lobushushu eliPhezulu eliPheleleyo eliSebenzayo eliQinisayo leSintering...

I-vacuum sintering furnace sisithando somlilo esisebenzisa ukufudumeza kwe-induction ukutshisa izinto ezishushu ngokukhusela.I-vacuum induction sintering furnace yiseti epheleleyo yezixhobo zokufakwa kwe-carbide kunye nomgubo wesinyithi ohlukeneyo ngokusebenzisa umgaqo wokufudumeza okuphakathi kwamaza omoya phantsi kwe-vacuum okanye iimeko zokukhusela umoya.Yenzelwe ukuveliswa kwemveliso ye-alloy enzima, i-metal dysprosium kunye nezixhobo ze-ceramic.

-

Ubushushu obuphezulu beGraphite Furnace

I-graphite furnace sisixhobo soshishino esinokwenza igraphite kwiindidi zamatye kunye neekhemikhali.Ingasetyenziselwa ukwenza izinto zegraphite ezinomgangatho ophezulu, ukusebenza okuphezulu kunye nokuhamba kombane okunamandla.Kukho iintlobo ezininzi zesithando somlilo segraphite, uhlobo lwenqwelomoya oluqhelekileyo, oluthe nkqo, uhlobo lokumiswa, uhlobo lolwelo njalo njalo.

-

Iziko lokuKhula leCrystal enye

I-crystal furnace enye ikwabizwa ngokuba yi-mono crystal furnace, sisixhobo esinyibilikisa izinto ze-polycrystalline ezifana ne-polysilicon ene-graphite heaterin i-inert gas (i-nitrogen kunye ne-helium gas) kwaye ikhulise i-crystals enye ngaphandle kokuchithwa ngokusebenzisa indlela yokutsala ngokuthe ngqo.

-

Isiko lokuNyibilikisa lokunyibilikisa leVacuum elungiselelweyo

Ukunyibilika kweVacuum Induction Melting (VIM) kukunyibilika kwesinyithi nge-electromagnetic induction phantsi kwevacuum.Isithando somlilo esine-refractory lined crucible ejikelezwe yi-coil induction ifumaneka ngaphakathi kwegumbi lokucoca.I-oven induction iqhagamshelwe kumthombo wamandla kwi-frequency ehambelana ngokuchanekileyo nobukhulu besithando somlilo kunye nezinto ezinyibilikayo.